Your Global Automation Partner

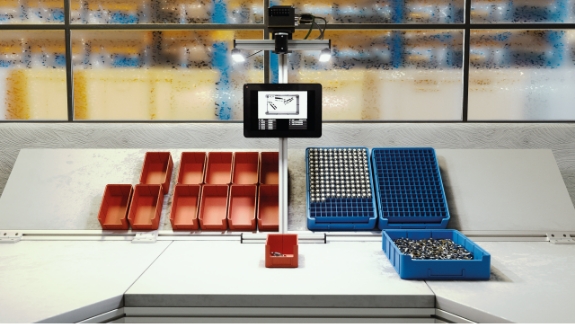

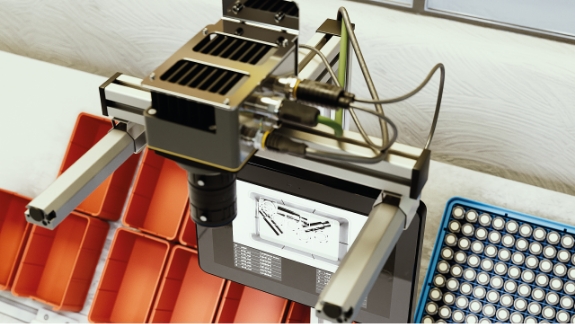

Self-learning AI Camera for Intelligent Inspections – Fast, Precise, Reliable!

Experience AI vision live – test TIV now!

Want to know what our intelligent vision solution can really do? Then simply send us some images from your application – our camera experts will analyze your requirements and carry out a free, customized feasibility test with TIV. This will give you a concrete idea of how TIV makes a difference: fast, precise, and reliable.

Fill out the form now!