Your Global Automation Partner

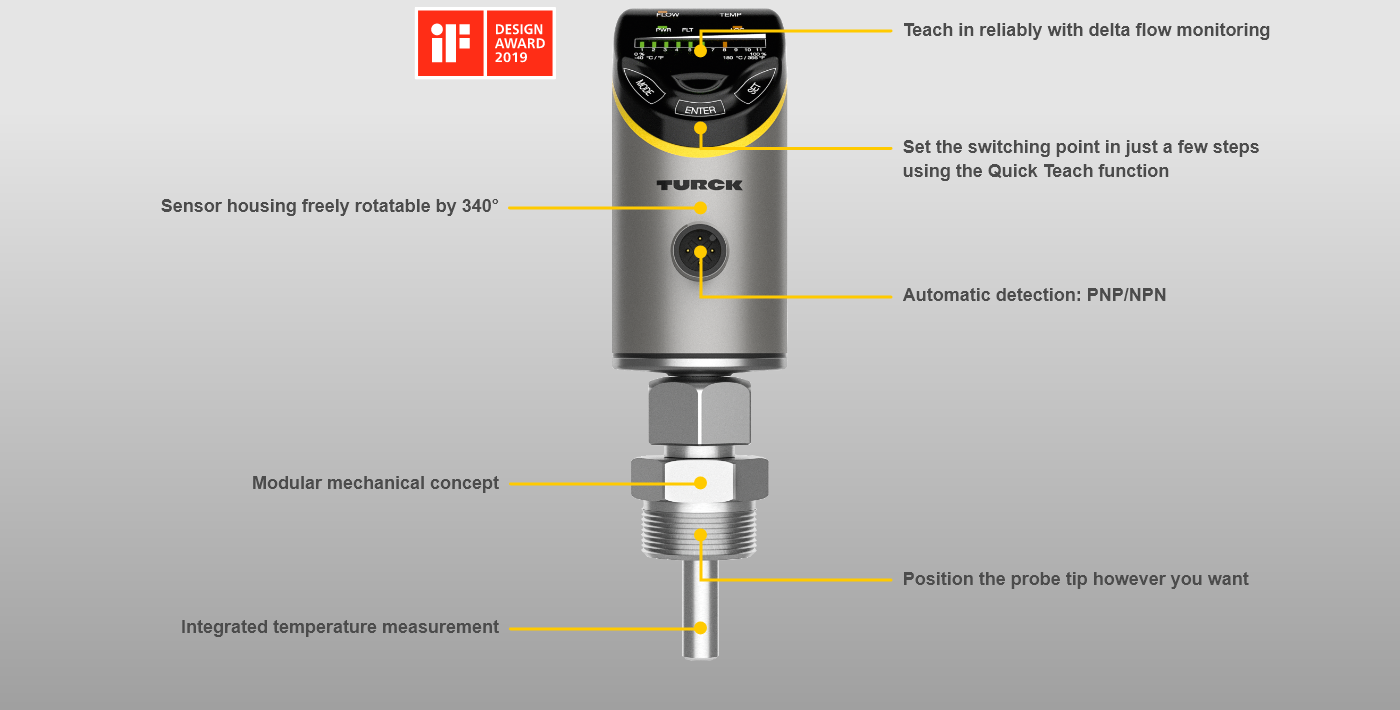

FS+ Flow Sensor for Monitoring Liquid Media

Technology should make your work easier and be readily available, intuitive and adaptable. A truly ingenious industrial design both amazes users and helps the product withstand harsh environmental conditions. This is why Turck's new FS+ flow sensor with IO-Link 1.1 has undergone many years of intensive development – to meet the most stringent of demands.

The compact sensor reliably and reproducibly monitors both the flow and temperature of liquid media. It is extremely easy to operate and its innovative sealing concept keeps it well protected against external influences.

Quick teach-in of the switching point

Users can quickly and conveniently integrate FS+ sensors into machines and plants. The sensors are easy to mount and can automatically detect PNP/NPN signals, while the Quick Teach function offers enormous advantages, such as allowing users to set the switching point directly on the device in a matter of seconds. Delta flow monitoring ensures that the teach point is taught in at the correct time.

Maximum Protection against Environmental Influences

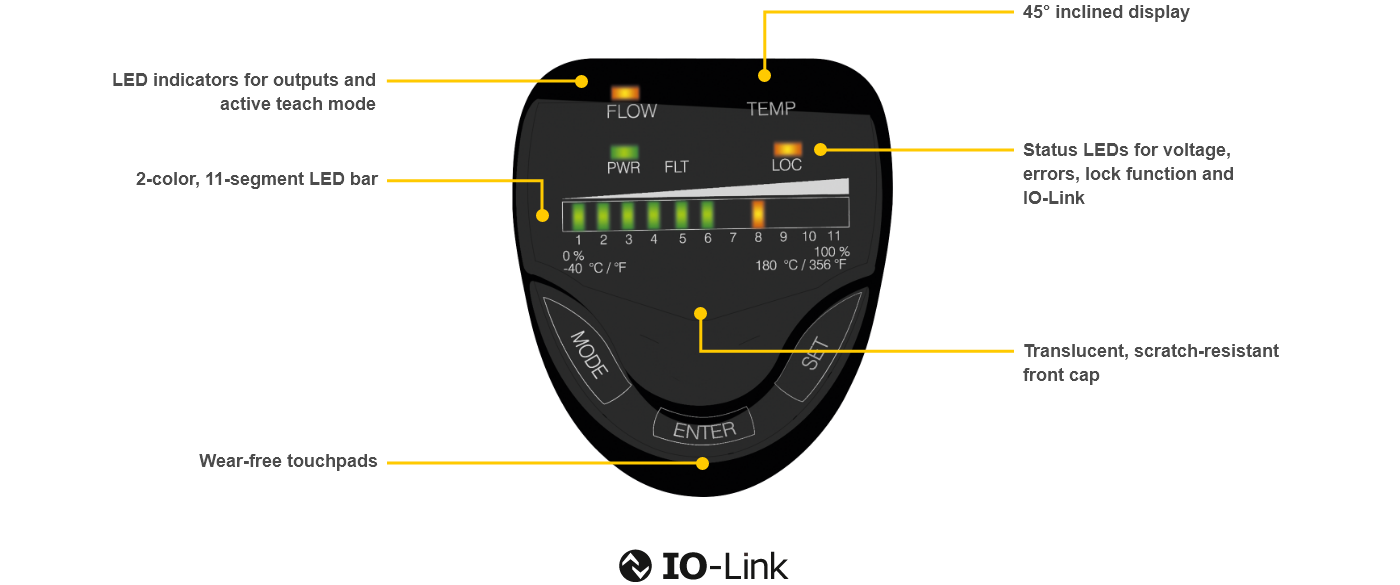

The flow sensor is operated via three wear-free touchpads. These allow you to navigate conveniently as you would on your smartphone, while also eliminating the need for additional sealing surfaces. Its stainless steel housing and one-piece cover help the FS+ sensor resist wear and meet the stringent requirements of the IP6K6K, IP6K7 and IP6K9K protection classes.

Easy to Mount and Set Up

A host of special features help you to commission the flow sensor as efficiently and easily as possible.

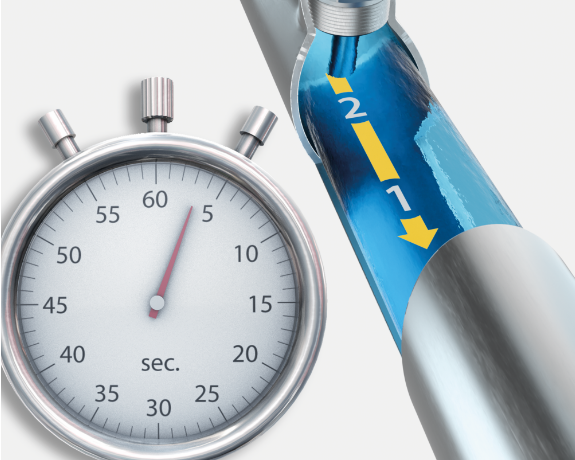

Speed Up the Teach Process

Quick Teach Function

You can set a switching point via the Quick Teach function in an instant or even directly on the device itself. The FS+ monitors the effective flow and alerts the user of any deviations from the reference value, which can be freely set by the user.

Delta Flow Monitoring

Delta flow monitoring ensures that all teach-in functions are only enabled once the flow is constant, so that users can rest assured that they are setting the switching point under the correct, desired conditions. This reliably prevents random or systematic errors from occurring during the teach process.

Operation via an Award-Winning Interface

The sensor's indicators and touchpads are durable and specifically designed to enable intuitive operation.

Modular Concept for a Varied Portfolio

The FS+ flow sensors are part of Turck's new platform for fluid sensors and follow a modular mechanical concept. The neutral M18 × 1 coupling nut allows you to adapt different process connections to your application. In addition, our sophisticated stock control system ensures the quickest delivery times. Probes are available in different lengths.

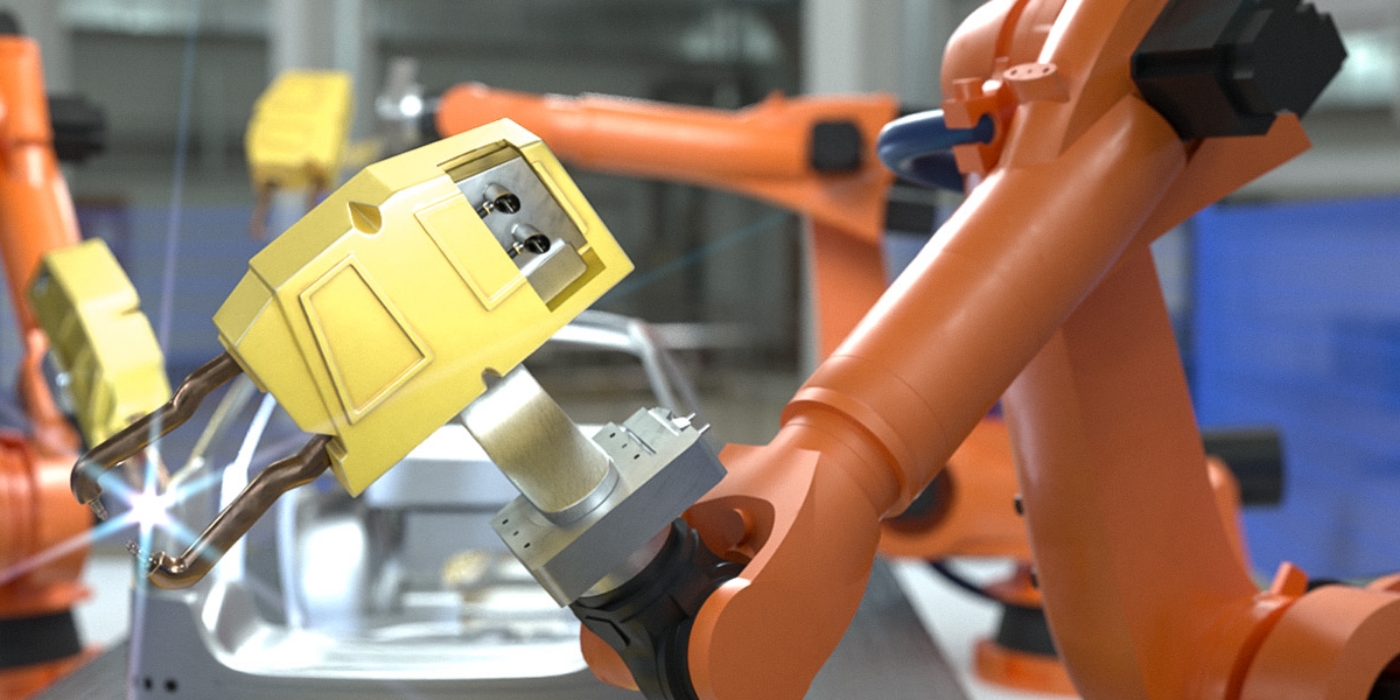

In the Video: Monitoring the Cooling Circuit on a Welding Robot

Production of automotive body parts primarily involves long cycle times and involves multiple welding robots working simultaneously, sometimes in extreme temperatures. See how FS+ flow sensors monitor the cooling circuit of a welding gun.

Ask an Expert

If you like to find out more about the possibilities for flow monitoring in your applications, contact our experts with any questions relating to fluid sensor solutions from Turck. Fill out the contact form to request the advice you need.

Raphael Scholzen