Your Global Automation Partner

Sustainability in Industry: Driving Change with Automation

Turck's digitally networkable solutions for efficient automation systems reconcile sustainability, profitability and efficiency. In this way, you not only increase your competitiveness, but also contribute to a more ecologically compatible production.

Economic and environmental sustainability have become central issues of our time. Industry is faced with the task of counteracting the effects of increasing energy and resource consumption and implementing sustainable solutions.

The challenges here are manyfold. Companies must integrate ecological aspects into their business models while remaining economically successful at the same time. In this respect, material consumption in particular is becoming an increasingly important factor for competitiveness due to rising raw material prices.

Smart automation concepts enable you to reduce ecological burdens, cut costs and strengthen your competitiveness. By using efficient and resource-saving production processes, companies can not only minimize their ecological footprint, but also be financially successful in the long term.

Turck's contribution to sustainable production through automation

As a globally active company, Turck relies on digital automation technologies to enable economically and ecologically sustainable solutions for industry. Factors such as effective energy management, efficient production and transparent supply chains are more than ever indispensable for implementing a successful and sustainable corporate strategy. Our solutions enable us to support you in overcoming these challenges, achieving your sustainability goals, and reducing costs in the long term – thus strengthening your competitiveness.

Efficiency, Effectiveness and Transparency: The Pillars of Sustainability

As an enabler for sustainable production and logistics, we support you in avoiding waste, saving energy and conserving resources.

Efficient production

Efficient and resource-saving production requires the intelligent control of materials and resources. Turck's automation solutions enable data-driven process optimization to avoid scrap and minimize resource consumption. This enables companies to achieve their sustainability goals, reduce costs and strengthen their competitiveness.

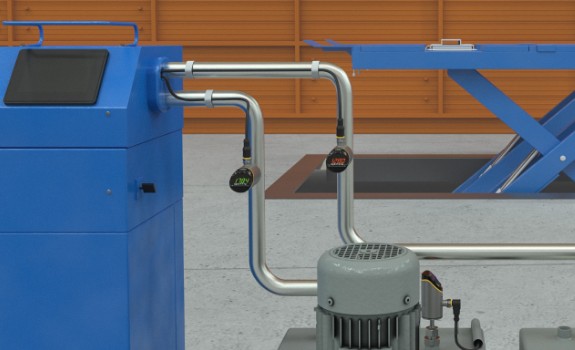

Effective energy management

The cheapest and cleanest energy is that which is not consumed in the first place. Data-driven automation solutions help to sustainably reduce energy requirements and thus save resources and costs. Efficiency improvements can be achieved through the intelligent control of energy flows, for example to avoid equipment idle times and unnecessary lighting or heating of buildings.

Transparent supply chains

Transparent supply chains are critical to achieving sustainability goals in industry. Data-driven supply chain traceability is an important building block of any sustainability strategy. With the help of track-and-trace solutions, companies avoid empty runs and know the location of goods and goods carriers at all times. This therefore enables optimum use of all available capacities.

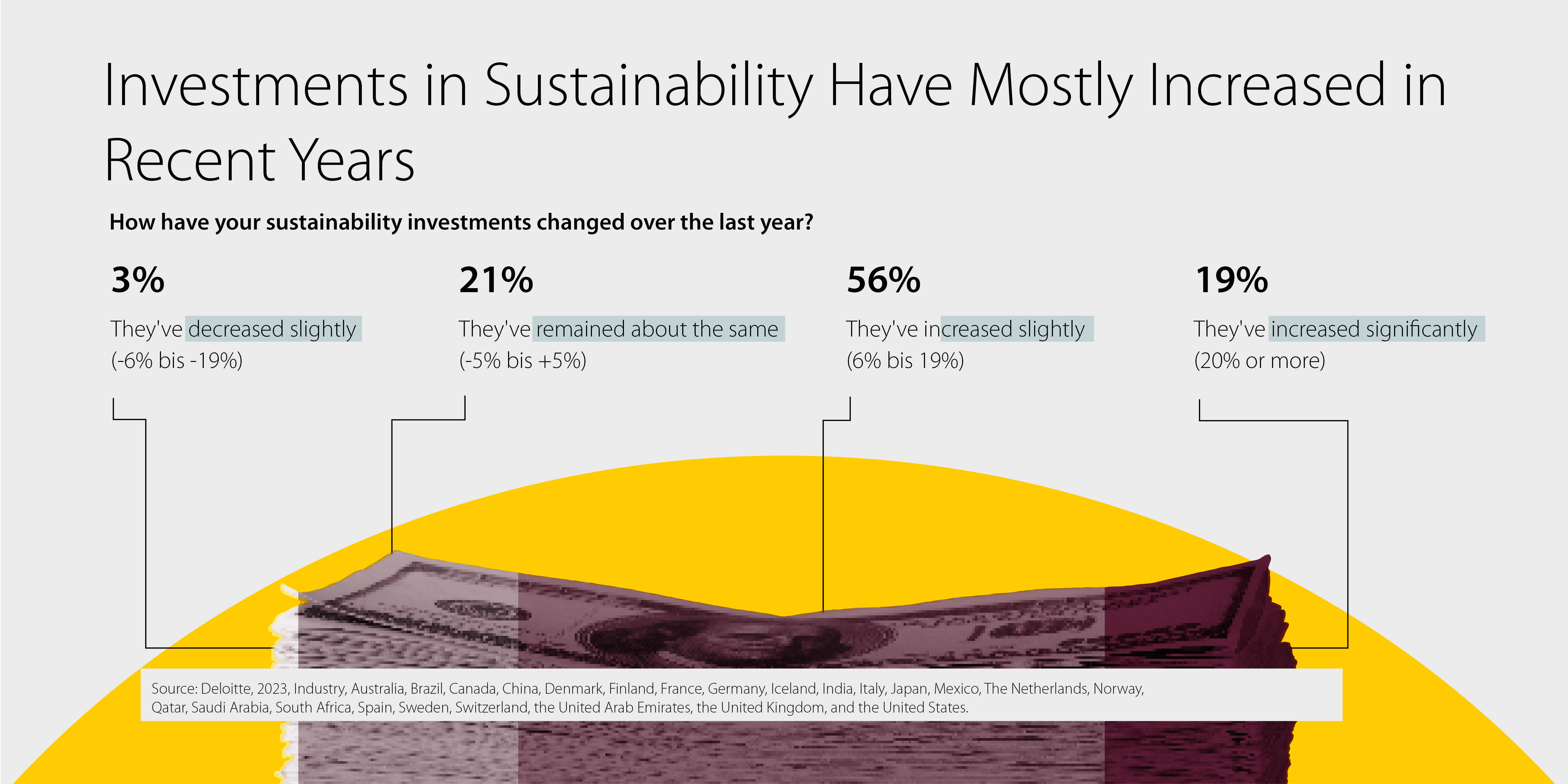

More and More Companies Are Turning to Digital Sustainability Technologies

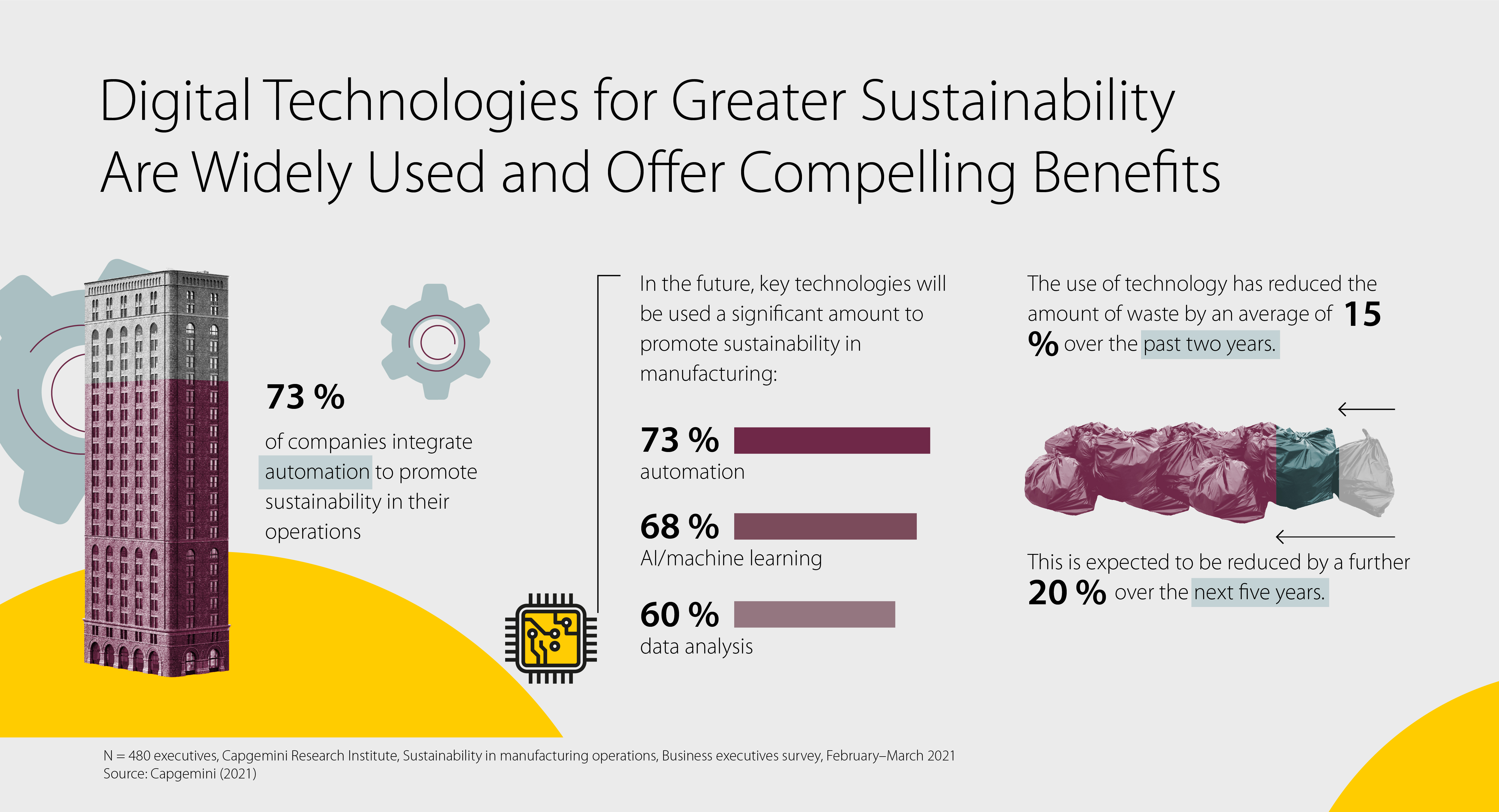

To drive sustainability in their operations, 73 % of organizations adopt automation.

Learn how companies are using digital technologies to increase the sustainability of their production processes. Automation, artificial intelligence and data analytics are major contributors, leading to significant increases in sales and profits. To make their manufacturing processes more sustainable, industrial companies are increasingly turning to digital technologies. Automation (73%), artificial intelligence (68%) and data analytics (60%) are some of the technologies most commonly used here. The implementation of these technologies has led to a significant reduction in waste while increasing profits at the same time. Companies using digital technologies are generally seeing an improvement in their revenue and profit metrics.

Sustainable Automation as a Success Factor

Read our whitepaper to learn how automation provides the basis for efficient production, effective energy management and transparent supply chains – enabling not only the achievement of environmental goals, but also cost reductions and competitive strength.

17 UN Sustainable Development Goals

With "Agenda 2030" and the 17 Sustainable Development Goals it describes, The United Nations has launched a global initiative to promote sustainable development. As a global partner for factory, process and logistics automation in numerous industries, Turck is making an important contribution to the implementation of the "Agenda 2030" and the achievement of its goals.

Efficient Production in Real Operation

Find out in the application examples how sustainable automation solutions enable efficient and resource-saving production - in a practical and vivid way.

Effective Energy Management in Practical Implementation

Read in the application examples, how data-driven automation solutions help companies to sustainably reduce energy requirements and thus save resources and costs.

Transparent Delivery Chains in Practice

In the application examples, you will learn how data-driven track-and-trace solutions help companies to achieve transparent supply chains and thus their sustainability goals.

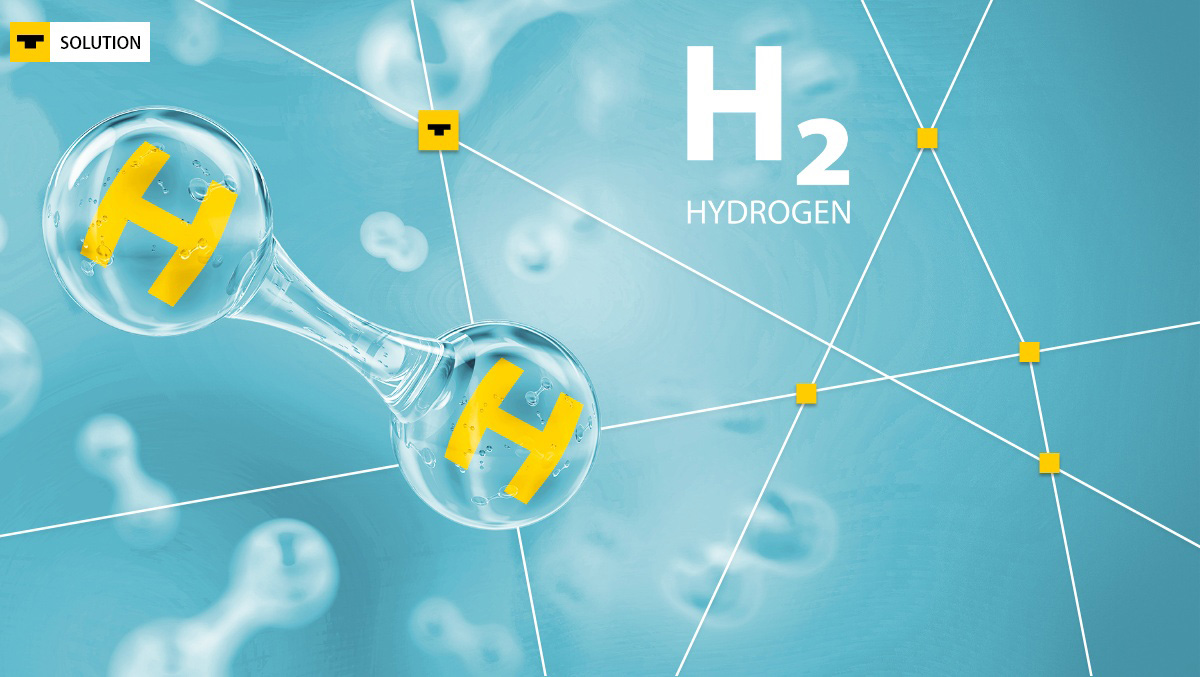

Implement Hydrogen Projects Quickly Thanks to Automation

Whether in electrolysis, transport, storage, dispensing, power generation with fuel cells or other applications – automation solutions from Turck get hydrogen projects to market faster.

To implement hydrogen projects quickly and efficiently, choosing the right automation solutions is crucial. Turck has decades of experience in the automation of plants that process explosive gases such as LNG or natural gas. This know-how and our broad range of solutions enable us to shorten the time-to-market for hydrogen projects and help replace fossil fuels more quickly. Our experts will advise you on the right solutions in order to avoid lengthy commissioning and troubleshooting. Rely on our experience and rely on automation solutions from Turck for the faster implementation of your hydrogen projects.

Intelligent Solutions for Sustainable Production

With its focus on sustainability and efficiency, Turck has established itself worldwide as a supplier of smart sensor and automation solutions. Discover our intelligent solutions for future-proof production and secure your competitive edge.

Codesys PLCs

PLCs with Codesys are particularly suitable for modular machines, because the open control software also makes it possible to build control programs with a modular design. You also benefit from the experience and work results of the Codesys community.

I/O modules with logic control function

All I/O modules with Turck multiprotocol Ethernet come as standard with some logic control functionality. The ARGEE programming user interface enables simple controller functions to be programmed on the module and executed by it – without the need to write program code or any additional costs.

Safety modules with integrated safety controller

IP67 block I/Os enable cabinet-free safety functions. With its safety controller, safety applications can be tested offline and controlled remotely in live operation.

RFID read/write devices and interfaces

Whether in the control cabinet or directly in the field as an IP67 complete system: RFID technology can decentralize decision making tasks and information, and thus help to increase flexibility and process safety.

IO-Link products

Turck's IO-Link portfolio offers an impressive level of seamless integration. As a full supplier from the device to the master side, Turck guarantees the easy integration of IO-Link devices in the controller environment.

HMI operating devices

HMI input systems in addition to the control system are used when information also has to be visualized and commands entered directly at the machine. The TX100, 500 and 700 series not only impress on account of the variety of interfaces available. There are no extra costs for licenses of the visualization software.

Condition monitoring sensors – for temperature, humidity and vibration

Environmental and plant variables that help to determine the condition of a machine are continuously recorded by Turck's condition monitoring sensors. IO-Link interfaces simplify system integration as well as the transfer of information.

TBEN-PLC – edge controller with CODESYS-3 PLC

Decentralized automation with simple integration for control tasks directly at the machine or plant. This leads to faster and more efficient processes, a reduction in cabling and therefore cost-optimized plant design.

TBEN – multiprotocol Ethernet I/O solutions in IP67

Easy integration into plants as well as diagnostic functions via integrated web servers even on smartphones enable high flexibility and mobility. The extensive diagnostic functions also reduce unexpected downtime through fast and precise troubleshooting.

Ask an Expert

Use or contact form if you have any questions on sustainable solutions or on a specific device. Our experts will be pleased to advise you.