Multitool for IIoT

The TAS Turck Automation Suite offers a multi-functional toolkit for the installation, service and management of Turck devices in automation networks

Quick Read

Turck’s TAS IIoT platform guarantees an easy-to-use and uniform overall solution for commissioning and managing Turck devices in Industrial Ethernet networks, from the sensor to the controller. Turck’s ARGEE logic software and BEEP IP address management solution are also integrated into the new multifunction tool, as well as device-specific apps for applications with IO-Link and RFID. TAS is regularly updated and extensive IIoT functions will be added for services such as condition monitoring or edge control on PCs or local servers.

In the age of digital transformation, software is also playing an increasingly important role in automation technology, as it forms the basis for controlling and monitoring automated processes. Software platforms and networked systems provide automated processes for faster and more efficient production. The software used in automation technology has to control and monitor complex processes, and so the requirements placed on it are high. On the one hand, it must be reliable and secure, as a failure can involve considerable costs. At the same time, it must be flexible and adaptable to meet the ever-changing demands of production. For all its functionality, the software should above all be simple and intuitive to use.

Besides network management and control technology, users also benefit from software solutions provided by automation suppliers, as they make the smart functions of previously simple devices such as sensors and actuators easy to access. A proprietary software also offers the user the chance to use a common ecosystem for all the automation solutions of a manufacturer and not to have to work with the different tools.

TAS IIoT and service platform

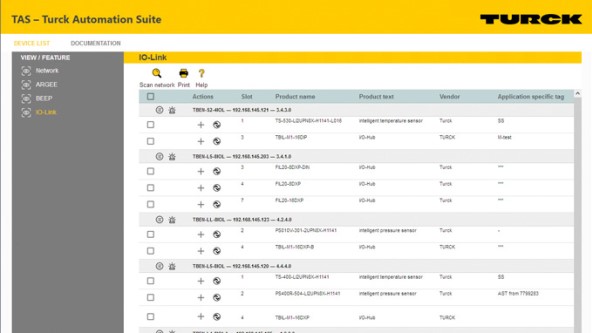

The Turck Automation Suite, or TAS for short, provides a new software platform that users can download free of charge and use directly in the web browser of any Windows PC without installation. TAS gives users a central tool to use and manage all the functions of Turck devices – starting with the sensor, to the fieldbus devices right through to edge controllers and PLCs. The devices can thus be set up and managed easily and quickly in industrial Ethernet networks. TAS also integrates an IODD configurator and provides access to all IO-Link functions of the Turck devices. The software suite thus combines a host of functions that were previously provided by individual programs, as well as many new functions, views and apps, such as the IO-Link View for an overview and management of the IO-Link masters and all connected IO-Link devices.

Batch functions for rapid commissioning in industrial Ethernet networks

The Network Scan function finds all available Turck Ethernet devices in the network and displays the relevant device information directly. Network View also enables the issuing of IP addresses and passwords as well as the execution of firmware updates for all devices in the network. The device specific web pages of all Ethernet devices can be accessed directly from TAS.

ARGEE and BEEP View

The ARGEE logic software turns Turck’s Ethernet I/O modules into IP67 logic controllers for cabinet-free operation directly in the field (field logic controller). Conditions and actions are thus programmable in the simplest way without any software installation required. ARGEE will not be able to replace every PLC, but the engineering software opens up new avenues in control technology, as it can relieve networks and higher-level controllers by executing simple logic tasks on site. This function is unique on the market to date. TAS allows you to load ARGEE programs conveniently on a group of devices in a batch process and manage them centrally. TAS also simplifies the management of BEEP configurations. Turck’s Backplane Ethernet Extension Protocol reduces the number of IP addresses required in industrial networks and simplifies the application of the TBEN and FEN20 multiprotocol block I/O modules. BEEP makes it possible to connect networks with up to 33 TBEN modules to the PLC via a single IP address in Profinet, Ethernet/IP and Modbus TCP networks. Through the reduction of the IP addresses, the user can quickly create high density I/O net-works and also connect them with low cost controllers.

Introduction Video: Turck Automation Suite (TAS)

Radar Monitor, IODD Configurator and more

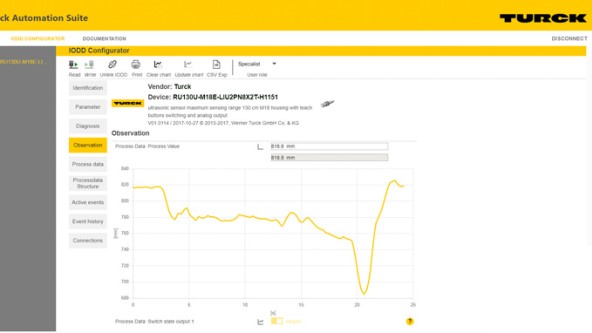

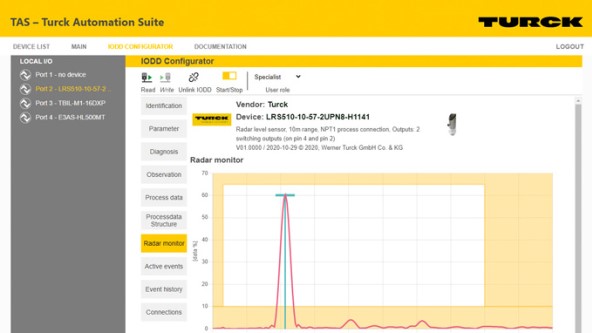

TAS also promises commissioning and management support for Turck’s IO-Link apps such as IODD Configurator, Radar Monitor, Vibration Monitor, etc. The user can call up and execute the respective app directly in the special IO-Link View.

The IODD Configurator, for example, can be used to parameterize IO-Link devices from all manufacturers. The app displays IO-Link process data in a graphical history curve, which is very helpful during setup. The user also has access to the plain text of all relevant parameters of the IO-Link devices used.

The Turck Radar Monitor offers similar benefits: It graphically displays the measured values of the Turck radar sensors and simplifies setup with a real-time display of the signal curve – especially when setting filters to suppress interfering signals or in complex mounting situations. Users can adjust filters, measuring windows and other parameters very easily to their particular application requirements.

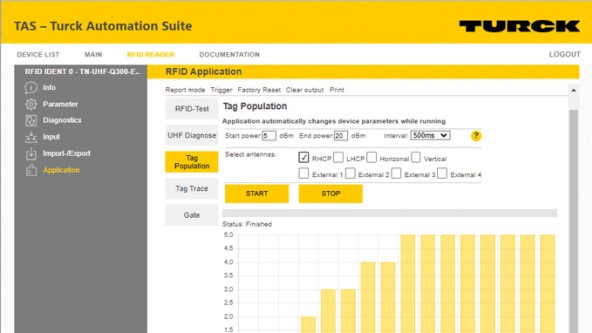

RFID Apps: UHF demo tools

For Turck’s RFID devices, TAS provides three UHF demo tools: “Gate Applications” simulates the bulk, i.e. simultaneous, detection of multiple tags in gate applications. The app checks whether all tags have been detected with sufficient certainty. Anyone who has ever had to assess a bulk detection operation manually knows how much time and effort this saves. “Tag Trace” enables users to determine the ideal start and stop times for optimum read and write processes in moving applications. “Tag Population” measures the read and write performance at different tag positions of a static object. For this, the UHF reader continuously increases its power and indicates the minimum power required to reliably read the tag.

IIoT platform with improved security

TAS improves the manipulation security of previous programs. All device actions have to be enabled with the device password. However, the password is saved for the duration of the browser session and can be applied if necessary to all devices with the same password, thus increasing user friendliness.

The best is yet to come: TAS IIoT platform

TAS version 1.7 is currently available but is only a foretaste of the range of functions of the fully developed IIoT solution. The software platform will be provided with additional functions and more digital services with every update. TAS will be provided with a connector function to the Turck cloud, by which it can be used as a virtual edge controller on a PC or local servers as well as on selected Turck devices. This will considerably simplify the smart evaluation of production data for condition monitoring and for predictive maintenance even beyond plant boundaries. To meet the requirements of an IIoT platform, TAS will also support the transfer of data via MQTT and OPC UA to higher-level systems, automatic configuration routines for service tasks and many other features. TAS will considerably increase the connectivity of your production system and thus combine OT data and IT data without any barriers.

Author | Christoph Schmermund is product manager for RFID interfaces

- Topics & Technologies

-turck-image.jpg)

-turck-thumbnail.jpg)