I/O Systems

Modular fieldbus I/O systems map the signal requirements of each application precisely and highly efficiently thanks to the individual composition of the electronic modules. They offer the advantages of a high level of intelligence, individualization and flexibility. In addition, modular systems shorten planning and commissioning times in project work and allow parallel connection to OT and IT networks.

The Turck BL20 I/O system is optimized for use in the control cabinet. BL67 is the equivalent of decentralized automation directly in the field. The highly available I/O system excom is designed and certified to meet the highest requirements in terms of availability and explosion protection in process automation, especially in the pharmaceutical, chemical, oil or gas industries.

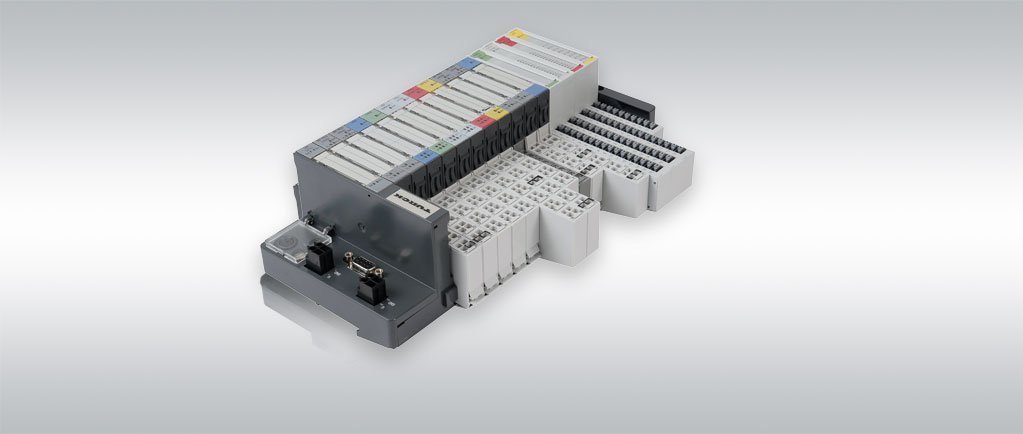

BL20 – Modular I/O System for Control Cabinet Installation

The BL20 modular IP20 I/O system is versatile due to its flexibility. The flexible combination of any gateway and I/O modules ensures the system structure is optimized to the application. Standing wiring and hot-plug also map functions of the process automation requirements. Eco modules allow cost-effective automation. Multiprotocol Ethernet means that the I/O system no longer needs to be replaced even when used with different control manufacturers. A fully fledged CODESYS-3 control function in the gateway allows fast and efficient automation as an option.

Gateways for numerous controllers PROFINET, Ethernet/IP, Modbus TCP, EtherCAT: PROFIBUS-DP, CANopen, DeviceNet, Modbus RTU/ASCII.

I/O modules allow precisely tailored solutions for every signal requirement: Digital and analog I/OS (optionally with HART, RTD and TC).

Numerous technology modules for IO-Link, Counter, SSI, PWM, RS232, RS485/422 as well as the BL ident RFID system.

Use in highly available and explosion-proof systems thanks to redundant supply modules, ring topology and Zone 2 approval.

BL67 – Modular I/O System for Use in the Field

The BL67 modular I/O system can be mounted directly in the field thanks to its IP67 protection class, making installation easier. The gateway is the interface to the control level. Due to the large number of gateways, which in turn can be combined with a wide range of I/O modules and basic modules, BL67 connects almost every signal to all major bus systems.

BL67 also offers a CODESYS-3 gateway which enables decentralized control of the I/O system directly in the field. It is also the only IP67 fully modular I/O system with multiprotocol communication.

Versatile: In addition to multiprotocol devices (PROFINET, Ethernet/IP, Modbus TCP), PROFIBUS-DP, CANopen and DeviceNet are also available.

The choice of modules ranges from digital, analog, and temperature modules, through to RS232, SSI, CANopen and other types with 2, 4, 8 or 16 channels.

Status LEDs on the module make it easy to diagnose and troubleshoot problems. Removing and inserting modules during operation (hot swapping) simplifies maintenance.

Valve terminals can also be integrated via 4, 8, or 16- channel digital output modules - or alternatively via CANopen modules.

The power-feeding module allows the feed-in of additional field supply. This also enables the formation of potential groups that can be switched off separately.

Modular machines Programmable CODESYS-3 gateways control directly from the field and thus relieve the load on the bus line as well as the main control.

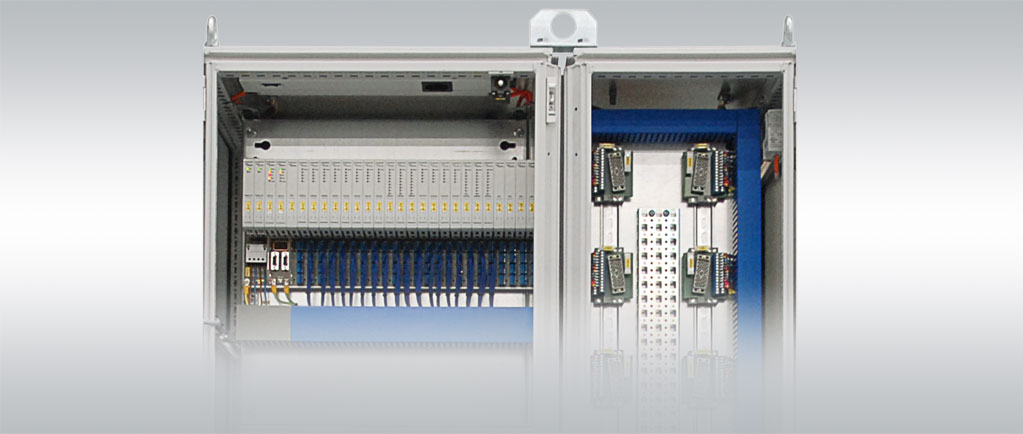

excom I/O in the I&C Room – Space-saving I/O System for Central Installation

excom for I&C rooms is a high availability fieldbus I/O system for central installations in process automation. It integrates explosion isolation and I/O level in one system. This saves users about one third of the space required for a classic installation with interface technology. For retrofits, excom scores with fast system installation and FAT outside the plant. Both—low space requirements and fast integration—are crucial for brownfield projects in the process industry.

The wide selection of electronic modules and module carriers for all signal types, integrated HART communication as well as power and communication redundancy make excom the ideal fieldbus system in the I&C room.

With the GEN-3G multi-protocol excom gateway, the I/O system can also be connected to control systems via the Ethernet protocols PROFINET, EtherNet/IP or Modbus TCP.

Together with standardized redundancy concepts, excom's dual power supply and gateways ensure maximum availability of your plant.

All excom modules are hot swappable. This means that they can be removed and inserted during operation, greatly simplifying system maintenance processes.

Configuration and parameterization during operation: excom's FDT-standardized DTMs and its HART transparency facilitate commissioning and maintenance.

excom can be connected to all common process control systems from ABB, Emerson, Honeywell, Siemens, Supcon, Yokogawa and Schneider Electric.

Removable screw or spring-loaded terminals as well as the diagnostic LEDs on the modules facilitate the handling of the system.

High signal density: excom can communicate up to 192 binary or 96 analog signals via a single bus address.

In addition to the process data, excom also cyclically transfers HART auxiliary variables. Sensors can therefore be used to transfer multiple measured variables.

High packing density on the module rails saves space in the I&C room.

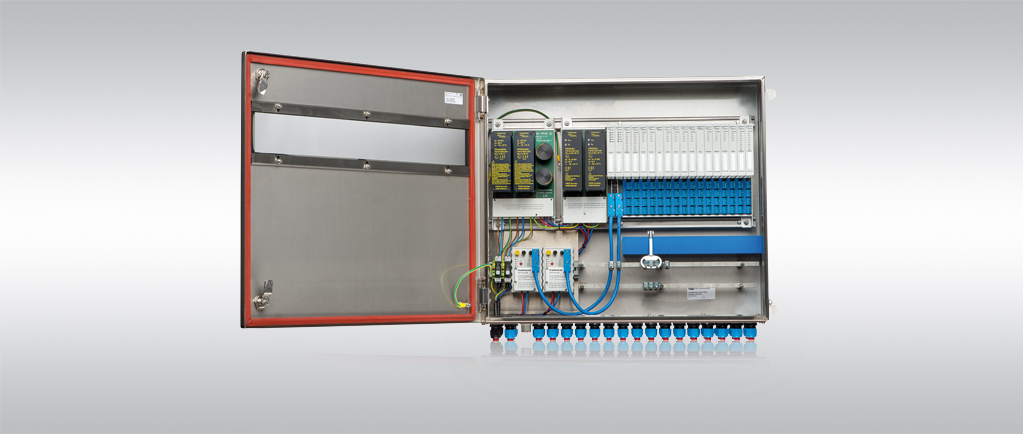

excom for Zone 1 and Zone 2 – Remote I/O System Kit for Remote Installation in the Field

excom can also be used directly in Zone 1/21. The field circuits are approved for Zone 0. Redundant power supply and gateways guarantee high plant availability.

This benefits the user not only in terms of components optimized for a particular zone, but also because of the standard concept for configuring and parameterizing the periphery and field instrumentation. For installations in Zone 1, panel rails for 8 or 16 modules are available – in Zone 2, the space-saving rack for 24 modules can also be used. The system can be ideally adapted to the space requirements and signal requirements of each application.

Together with standardized redundancy concepts, excom's dual power supply and gateways ensure maximum availability of your plant.

All excom modules are hot swappable. This means that they can be removed and inserted during operation, greatly simplifying system maintenance processes.

Changes to configuration and parameterization during operation: excom's FDT-standardized DTMs and HART transparency facilitate commissioning and maintenance.

excom can be connected to all common process control systems from ABB, Emerson, Honeywell, Siemens, Supcon, Yokogawa and Schneider Electric.

Removable screw or spring-loaded terminals as well as the diagnostic LEDs on the modules facilitate the handling of the system.

High signal density: excom can communicate up to 192 binary or 96 analog signals via a single bus address.

In addition to the process data, excom also cyclically transfers HART auxiliary variables. One sensor can therefore transmit multiple measured variables.

Due to the high packing density on the module rails for 8, 16 and 24 modules (zone 2), small switch cabinets can be used on site.

Predicitve Maintenance in Hazardous Locations

Turck's excom Ethernet gateways transfer selected data to local servers, the Turck cloud or other cloud services, ensuring high transparency and security.

Elevator Pitch: excom Ethernet Gateway for Zone 2

Turck's excom Gateway GEN-3G brings signals from zone 0 with high data rates into control systems.

Downloads

General Catalog - Factory Automation Products - Download (43634 KB)

General Catalog - I/O Solutions for the Control Cabinet - Download (16192 KB)

Product Overview - excom I/O system - Download (6454 KB)

Product Overview - Products and Solutions for Efficient Automation - Download (2182 KB)

Product Overview - Solutions for Factory Automation - Download (1559 KB)