Product Manager Christoph Schmermund is convinced by the functions and advantages of Turck´s IIoT platform

Seamless Monitoring and Communication Thanks to Turck Automation Suite

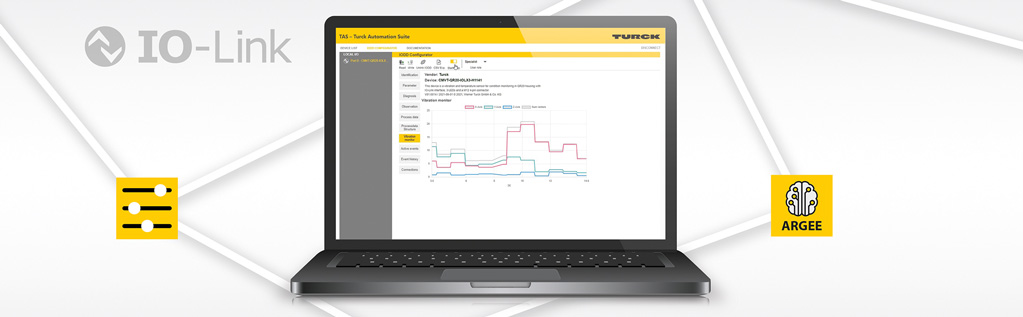

The Turck Automation Suite (TAS) provides engineers and technicians with a comprehensive IIoT platform that supports device management, commissioning and the continuous monitoring of plants. Product manager Christoph Schmermund spoke to Frank Nolte, editor-in-chief of SPS-Magazin, about the features, types and areas of application of the software platform.

The networking of machines and systems plays a central role in modern industrial automation. With the increasing integration of sensor technology and decentralized control systems, the need for intelligent IIoT platforms that enable end-to-end communication and monitoring is growing. This is where the Turck Automation Suite (TAS) comes in, which has been available since the end of 2022. The TAS Cloud module was added to the IIoT platform for configuration, parameterization and commissioning for Hannover Messe 2024. The previously available TAS set of service tools will be further developed under the name TAS Desktop. Release 1.11 has just come out and this brings new functions and a large number of improvements, particularly for TAS Desktop. The IIoT and service platform will be completed in the medium term by TAS Edge with tools for edge computing on Turck hardware and TAS Mobile, a special version for mobile devices.

Efficient device management and fast commissioning

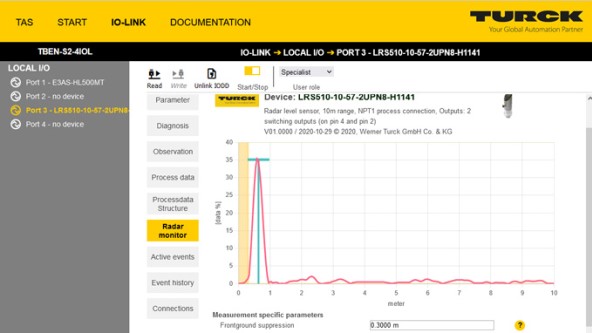

TAS Desktop is the first pillar of the Turck Automation Suite. It focuses on simplified and structured device management as well as quick and easy commissioning of devices. “TAS Desktop enables users to put many devices into operation with just a few clicks, thus saving a lot of time,” product manager Christoph Schmermund emphasizes and continues: “Its outstanding features include the support provided for troubleshooting and the efficient implementation of firmware updates. This allows users to carry out tests without having to do any programming.

Schmermund gives an example of this with the evaluation of an RFID sensor: “Commissioning this kind of sensor previously required the creation of a PLC program, uploading it to the PLC and possibly the creation of a user interface. With TAS Desktop, these tasks can now be carried out directly via the desktop tool. The measurement results of the sensor are visualized, which considerably simplifies evaluation and parameterization.”

“This simplification also enables the efficient implementation of feasibility studies for RFID systems and the management of all Turck devices within a production network,” Schmermund adds and continues. “The network scan function identifies all available Turck Ethernet devices in the network and makes their device information directly available. This view also makes it easier to assign IP addresses and passwords and to carry out firmware updates for all devices in the network.”

Introduction Video: Turck Automation Suite (TAS)

Logic software included

Another feature of TAS is the ability to execute many functions of the network view as a batch function. This enables the simultaneous configuration and processing of many devices, which saves time, especially in large networks – and without the need for third-party software. The Argee logic software transforms Turck‘s Ethernet I/O modules into IP67 logic controllers for use directly in the field as so-called field logic controllers. “This function is unique on the market. TAS thus makes it possible to load Argee programs conveniently and manage them centrally on a group of devices using the batch function,” Schmermund says.

The Codesys view in TAS enables almost all Turck controllers in the network with Codesys to be displayed and the controller programs of the connected devices to be downloaded and saved. Users can also run or stop the programs in cold or warm start via TAS. TAS Desktop also offers a comprehensive service concept with updates, efficient fault analysis and user-friendly visualization of device data. By integrating the smart M12Plus Bluetooth connector, which can measure voltage curves and transmit the values via Bluetooth, TAS Desktop also offers a solution for detecting impending cable breaks, resistances or other faults.

Continuous monitoring and intelligent data acquisition

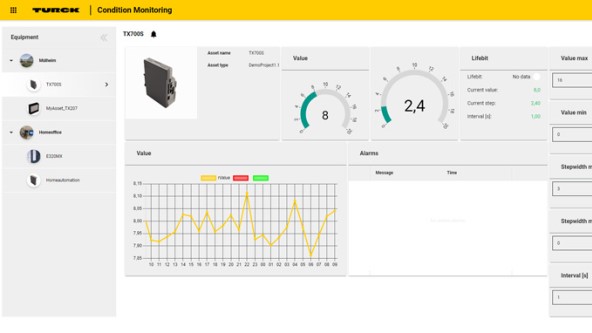

While TAS Desktop is primarily used for event-based work, TAS Cloud offers a solution for the continuous monitoring of machines and systems. TAS Cloud enables 24/7 condition monitoring, in which all relevant values can be recorded and alarm messages issued.

A central feature of TAS is the ability to automatically recognize and configure devices when they are replaced. This considerably reduces the effort for the user, as no manual adjustment by an installer is required. Continuous central network monitoring and backup and restore functionalities round off the TAS offering. “TAS can be operated both locally and in the cloud. Thanks to the support of numerous OT protocols such as Profinet, Profibus and Modbus, seamless integration into existing automation infrastructures is possible,” Schmermund emphasizes.

Central data management and intelligent analyses

TAS Cloud enables centralized management and analysis of the data collected from different devices and locations. The functions include the creation of dashboards, the management of alarm systems and the running of maintenance tasks. This not only makes it easier to monitor and maintain systems, but also to optimize processes through data-based decision-making.

Schmermund offers a glimpse into the future: “The central platform for analyzing machine data supports the implementation of predictive maintenance and condition monitoring. “A great feature in TAS Cloud is the Maintenance Manager, which simplifies guided maintenance and commissioning through digitalization and standardization and thus efficiently compensates for disadvantages caused by inexperienced personnel. TAS Cloud will be further developed in future so that users won‘t even notice whether they are in the web browser on the edge, on the desktop or in the cloud.”

The introduction of TAS Mobile is also planned, which will enable the use of TAS on mobile devices. This would allow users to carry out configurations or analyses directly via their smartphone.

Support for standards

A major benefit of the Turck Automation Suite is the broad support of standard protocols such as Profinet, Ethernet/IP, Modbus TCP and many more. This enables easy integration with a wide range of devices and systems, both from Turck and from third-party suppliers. Particularly noteworthy is the support of IO-Link or DCP, which means that TAS can also be used with third-party devices as long as they comply with the relevant standards.

“The support of protocols such as MQTT and OPC UA also makes it possible to seamlessly connect OT data with IT systems and improve connectivity within the production environment,” Schmermund explains, emphasizing the uniqueness of TAS: “The Turck Automation Suite stands out from other automation platforms primarily on account of its comprehensive management and configuration functions. The batch functions in particular make it possible to carry out many actions simultaneously for several network devices, which saves a considerable amount of time, especially when assigning IP addresses or updating firmware. This central management function is unique.”

The integration of predictive security technologies and data protection-compliant monitoring methods will also be part of the TAS platform. These functions help to increase the safety and efficiency of industrial processes.

Conclusion: the future of automation with TAS

The Turck Automation Suite offers a comprehensive solution for the requirements of modern automation. With its four pillars – TAS Desktop, TAS Cloud and soon TAS Edge and TAS Mobile – it covers all important areas, from commissioning and continuous monitoring to centralized or decentralized data management and analysis. An engineer can use TAS Desktop to commission and manage all machines quickly and efficiently. TAS Edge will add powerful edge computing capabilities to the platform, enabling local processing of data for faster responsiveness. The collected data is then analyzed in TAS Cloud to optimize processes and identify potential problems at an early stage. By supporting common protocols and working with Codesys, TAS is a flexible and future-proof solution that can be seamlessly integrated into existing systems.

Author | Frank Nolte is editor-in-chief of the trade magazine SPS-Magazin

- Topics & Technologies

-turck-image.jpg)

-turck-thumbnail.jpg)