Self-learning AI Camera

TURCK Intelligent Vision (TIV) brings artificial intelligence directly to the line – robust, flexible, and fast

With its new AI camera TIV, TURCK promises a paradigm shift in industrial image processing: instead of complex programming, all you need to do is train the intelligent camera with a few sample images. TIV (TURCK Intelligent Vision) learns patterns and differences independently and reliably recognizes good and bad parts or different classes. The training and execution of the neural networks takes place directly on the camera, supported by a powerful 12-megapixel global shutter sensor (Sony Pregius S, 4th generation) and an NVIDIA Jetson Nano GPU with 4 GB RAM. Image processing runs in real time on the device.

Your Benefits

- Quick commissioning without programming

- Stand-alone in IP67, no additional edge hardware

- Real-time results, scalable through transferable networks

Flexibility and efficiency for practical use

With four pre-installed AI apps – Difference Check, Classifier, Detector, and Code Scan – the TIV12MG-Q110N covers key industrial image processing tasks: from completeness checks and classification to object detection and 1D/2D code recognition. The camera recognizes and evaluates test areas separately, delivering coordinates, confidence scores, and IO/NIO signals directly to PLCs or IT systems. Thanks to the C-mount connection, standard lenses can be used flexibly; an optional protective tube brings the system up to IP67 protection class. The entire control system, lighting technology, sensors, and power supply are decentralized and robust – ideal for use directly on the line.

Seamless integration with TAS

Operation is intuitive via the web browser. Integration into the TURCK Automation Suite (TAS) facilitates device management and integration into digital maintenance and monitoring processes. M12 connections for power, network, trigger, and I/O allow the camera to be flexibly integrated into existing systems. On-premise operation, transferable data sets, and neural networks enable scalable rollouts without additional edge hardware or licensing costs.

INDUSTRIES

- Intralogistics and packaging

- Assembly and manufacturing

- Sorting and identification applications

KEY FEATURES

- Difference Check (target/actual comparison via ROIs)

- Classifier & Detector (classification, detection including coordinates and confidence score)

- Code Scan (1D/2D, type/position/content), can be combined with Detector

- Powerful 12 MP sensor, NVIDIA Jetson Nano, C-mount, M12 connectivity

RELATED CONTENT

Nominated for Reader's Choice Award

The trade journal Computer&Automation has nominated our AI camera TIV (TURCK Intelligent Vision) for the reader's choice award “Product of the Year 2026”. Vote now!

Expert Talk: AI Camera TURCK Intelligent Vision (TIV)

Technical Trainer Jörg Tauert and Raphael Penning, Product Manager Distance Sensors, talk about the functions, benefits and possible applications of TURCK´s new TIV AI Camera. Watch now!

Walk & Talk: AI Camera TURCK Intelligent Vision (TIV)

Get an overview of features and benefits from our product expert. Watch now!

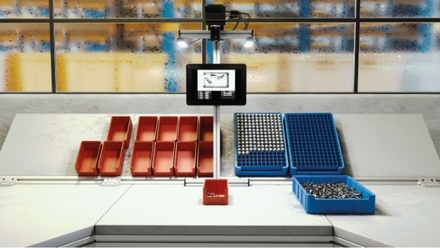

Application: AI Camera Ensures Error-Free Kitting

TIV camera uses machine learning to recognize objects and check the correct composition of sets. Learn more in our TIV application!

Application: AI Camera Guarantees Error-Free Placement

Difference Check enables the AI-supported TIV camera to reliably detect errors in assembly processes. Learn more in our TIV application!

PRODUCT DATA

All Details about the AI Camera TURCK Intelligent Vision (TIV)

Approvals, data sheets, technical specifications, instructions, certificates, CAD data, and more